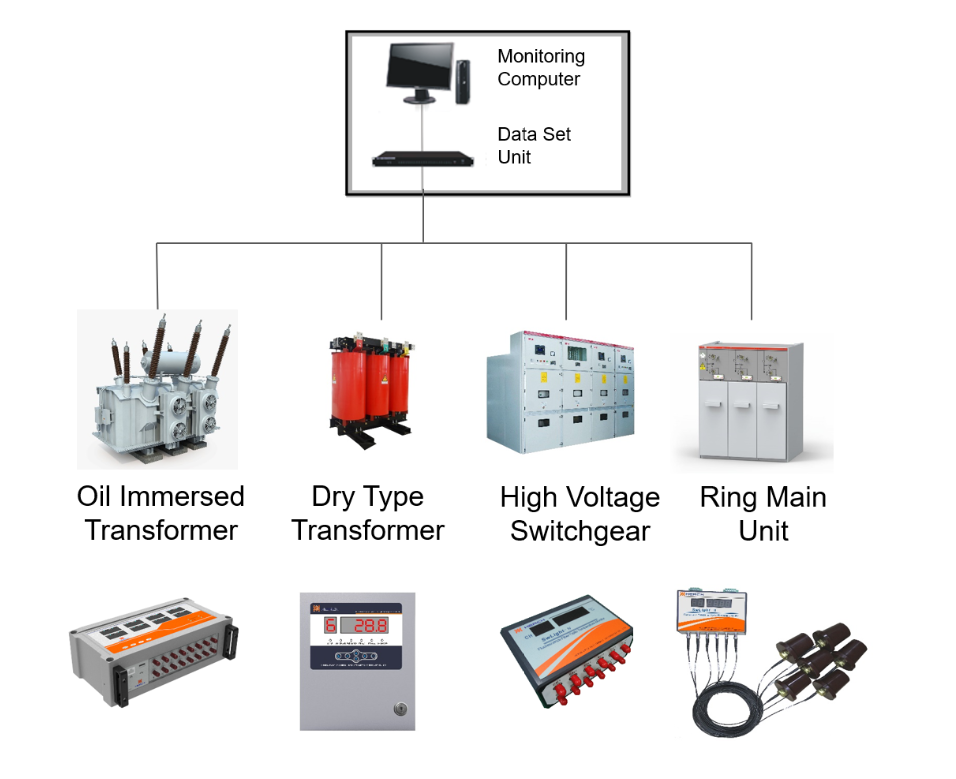

Fluorescent Optical Fiber Temperature Measurement Solution for Power Supply Special Contact in Rail Transit Industry 1. Introduction The on-line monitoring system for power-specific contact optical fiber in the rail transit industry is specially designed to ensure the safe operation of high-voltage power equipment (such as transformers, switchgears, cable joints, and rectifiers) along the railway substation. The temperature difference between substations along the railway is large, and the vibration is frequent when the train passes. When these key equipment are used for too long, overload, insulation aging or poor contact, local overheating will occur. By monitoring the temperature of multiple points in the equipment in real time, it is possible to predict possible failures and effectively prevent accidents. The on-line monitoring system for power-specific contact fiber in the rail transit industry is mainly composed of optical fiber temperature sensor, fluorescent fiber demodulator, monitoring host and human-machine exchange software.

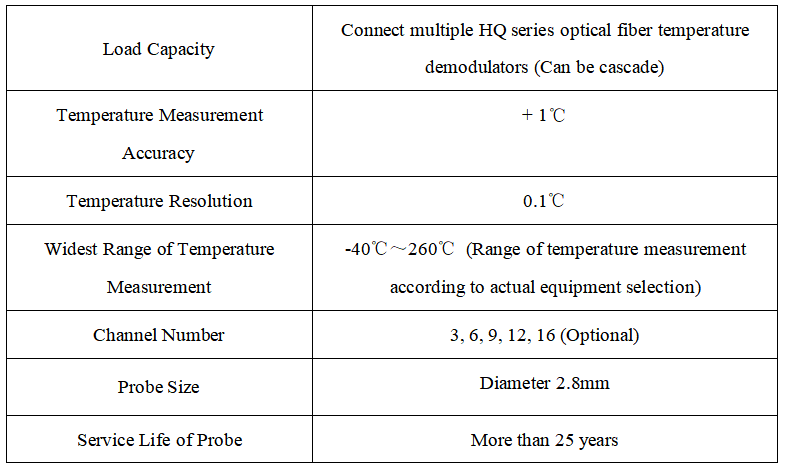

2. Technical Advantages The comparison of several main temperature measurement methods in the field of electric power at present: 2.1 Infrared Thermal Imaging Temperature Measurement System Advantages: 1. Non-contact temperature measurement, and easy to operate; 2. Low cost. Disadvantages: 1. The measurement is inaccurate, only the surface temperature can be measured, the real temperature of the internal hot spot cannot be measured; 2. Handheld, and cannot achieve online monitoring; 3. Artificial inspection, increase labor costs, the minimum annual labor costs of more than 100,000 Yuan. 2.2 Wireless Temperature Measurement System Advantages: 1. Easy installation; 2. Low cost. Disadvantages: 1. Poor reliability, with battery measurement, short life; 2. The insulation performance of cabinet is affected, so it cannot pass the test; 3. The large volume of the sensor affects the heat dissipation function; 4. The surface temperature can only be measured, but the real temperature inside the hot spot cannot be measured. 2.3 Fiber Bragg Grating Temperature Measurement System Advantages: 1. Quasi-distributed temperature measurement can be realized, which is suitable for long-distance and large-area areas; 2. With optical fiber technology, the insulation performance is good. Disadvantages: 1. Difficult to install; 2. Cannot achieve a single cabinet matching, cannot achieve in-situ display. 2.4 Fluorescent Optical Fiber Temperature Measurement System Advantages: 1. Its performance is safe and reliable, and it can achieve calibration-free, good consistency, interchangeability and stability; 2. Long service life, maintenance-free. Minimum use of optical fiber sensors for 25 years; 3. The probe is small in size and can be used to measure the hot spot in depth, so as to realize the real and effective monitoring of the hot spot; 4. Anti-electromagnetic interference, good insulation performance, integrated into intelligent switchgear and passed the type test; 5. It can be displayed locally and integrated into the control system conveniently. 6. Easy installation and flexible networking; 7. High cost performance ratio. Disadvantages: 1. The measuring distance is relatively short, usually in the order of 100 meters. For the node temperature measurement of electrical equipment in power plants and substations, Herch’s fluorescent optical fiber temperature measurement has obvious advantages: no electrical interference, small size, long life, independent networking, and high reliability. 3. System Characteristics ? Guarantee the ideal isolation of primary and secondary power, good linearity and high accuracy; ? Multichannel transmission: The information collected by the system can be uploaded and dispatched by FTU, GPRS or communication management unit in the box, and the transmission mode can be flexibly selected according to the field environment; ? Do not reduce the safety level of electrical equipment: Temperature-measuring fluorescent optical fiber fire detector is small, 2.8mm in diameter, without any metal materials, electronic components, good insulation, 20cm withstands 100,000 volts voltage; ? Full-year, all-weather security guardian: At least 25 years, 365 days a year, 24 hours a day real-time monitoring and analysis; ? It reduces the blind area of monitoring and improves the safety of equipment: Positioning accuracy is 1 mm; ? Cost savings: Directly installed in the temperature rise part, real-time recording and displaying monitoring point data to achieve unattended monitoring station objectives; ? Maintenance basis is established: Fully grasp the operation of the equipment, can predict the aging of the equipment, so as to put forward the maintenance time and maintenance plan according to the operation status of the equipment; ? Intelligent judgment: It can quickly judge and analyze the normal temperature, abnormal temperature and fire of the tested object. 4. Major Performance Indicators

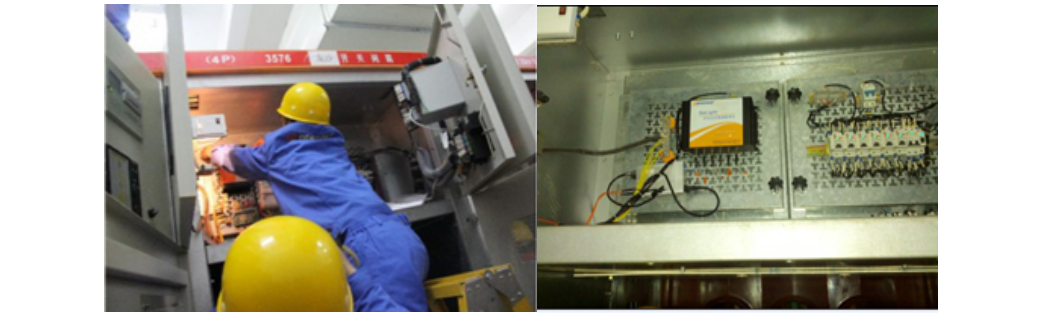

5. Introduction of Main Components The HQ series fluorescent optical fiber temperature monitoring system is selected as the on-line monitoring system for electric power connection in rail transit industry. A set of system is mainly composed of several optical fiber temperature sensors, a multi-channel optical fiber demodulator, monitoring host computer and human-machine exchange software. 5.1 HQ Series Fluorescent Fiber Temperature Demodulator HQ series fluorescent optical fiber temperature demodulator receives real-time optical signal with temperature information from temperature-measuring fluorescent optical fiber fire detector, and demodulates it to temperature value to realize temperature measurement of monitored parts. When the actual measurement value is larger than the alarm setting value, the alarm signal sent out. They can work independently on a single computer, or can be used in multiple networking, and are suitable for application requirements of various scales. 5.2 Temperature-measuring Fluorescent Optical Fiber Fire Detector The probe size of temperature-measuring fluorescent fiber-optic fire detector is very small and can be directly installed at the measured point, which can measure temperature accurately and respond quickly. Its tail fiber is made of soft and strong special optical fiber, which has the advantages of high transmission bandwidth, stable signal, anti-electromagnetic interference, anti-flexure, high impact strength and fast connection. The tail fiber sheath has the characteristics of high temperature resistance, aging resistance, corrosion resistance, high insulation, non-adherence and so on. It can adapt to the harsh environment of high voltage, high temperature, strong electromagnetic and so on. 5.3 Monitor Host The monitoring host can receive and process the normal information, fault information and disaster information from the optical fiber temperature demodulator in real time, and quickly process and manage them. The monitoring host has the functions of fault monitoring, display, alarm and information exchange. At the same time, the remote monitoring can be realized through the network. 5.4 Men-Machine Interface The main functions of the software system include real-time temperature local monitoring, real-time data remote monitoring, high/low temperature alarm, high/low temperature early warning, historical data playback, pre-alarm and post-alarm curve, temperature export to Excel and other functions. 6. Construction cases ? Installation of monitoring host: The monitoring host of this system is installed in the monitoring cabinet of the substation control room, and a monitoring computer is set up in the central control station for remote monitoring. ? Installation of HQ Series Optical Fiber Temperature Demodulator: The demodulator is installed on the back wall of the instrument panel in front of the switchgear to facilitate future maintenance.

Box Substation Installation

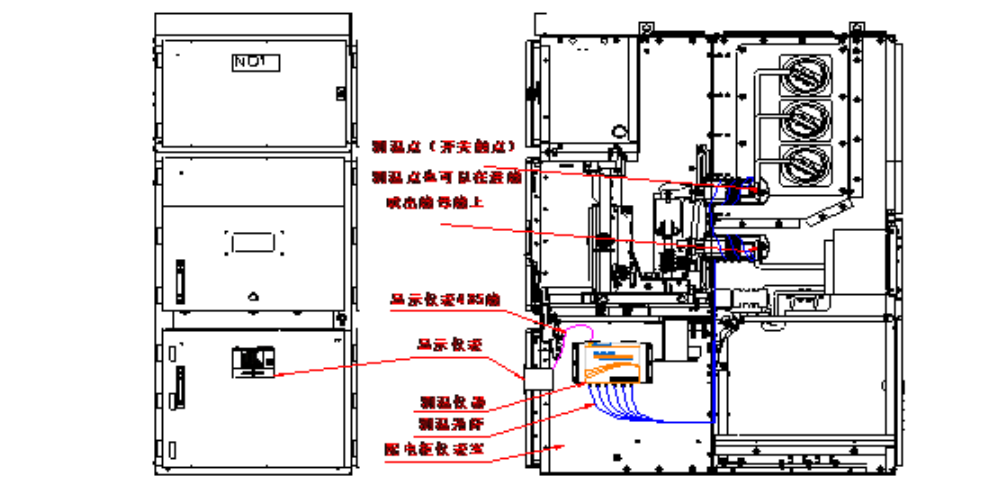

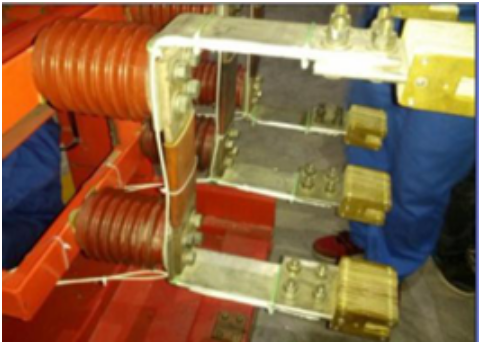

Schematic Diagram of the Layout of the Switchgear in the HQ Series Fluorescent Optical Fiber Temperature Monitoring System ? Installation of HQ-12 Temperature-measuring Fluorescent Optical Fiber Sensor 1. Installation on Switchgear Contacts

The main hotspot of switchgear is located at the joint of static and dynamic contacts, but this part is protected by insulating sleeve, and the space inside is very narrow. In order to measure the heating temperature of contacts more accurately, the diameter of HQ-12 temperature-measuring fluorescent optical fiber sensor is 2.8mm. It can extend into the inner of the sleeve from the rear of the sleeve along the confluence row. A high temperature resistant and high insulation installation clamp is designed specifically for the static contacts, which can fix the sensor firmly on the static contacts. When fixing the fluorescent optical fiber fire detector with a clamp, the sensor head is fixed in the fixed groove of the sensor first, and then the clamp and the sensor head are clamped on the cylinder of the static contact. During installation, the clamp is installed at the joint of the static contact and the bus bar to keep a safe distance from the movable contact. 2. Installation at Cable Joint of Switchgear

The fluorescent optical fiber fire detector for temperature measurement was pasted on the cable joint with special aviation silica gel and fixed with special strapping. After the installation of the temperature-measuring fluorescent optical fiber fire detector is completed, the tail fibers are tied to the copper bars connected with the rear of the static contacts with insulating straps to prevent the temperature-measuring fluorescent optical fiber probe from hitting the adjacent contacts in case of falling off. ? Inside Cabinet Wiring In order not to affect the electrical distribution in the cabinet, as well as the future overhaul of the cabinet, cables and tail fibers in the cabinet should be as far as possible along the corner of the cabinet, or take a special trunk or bundle with the secondary cable in the cabinet.

? HQ series transformer winding temperature measurement system, the optical fiber sensor probe is installed in winding coil in the process of transformer fabrication. Through flange penetrator, the internal and external optical signals are docked, and the temperature measurement host is analyzed and demodulated to realize real-time on-line temperature measurement. ? Background communication: Real-time temperature data of field power equipment are uploaded to the backstage monitoring system through 485 parallel lines or optical cable transmission. ? About insulation and anti-creeping: Temperature-measuring fluorescent optical fiber fire detector has high insulation, anti-creeping, anti-corrosion. Attachment: Product Model

|

CONTACT US

CONTACT US MESSAGE

MESSAGE